Band

Saw Machine

Discover

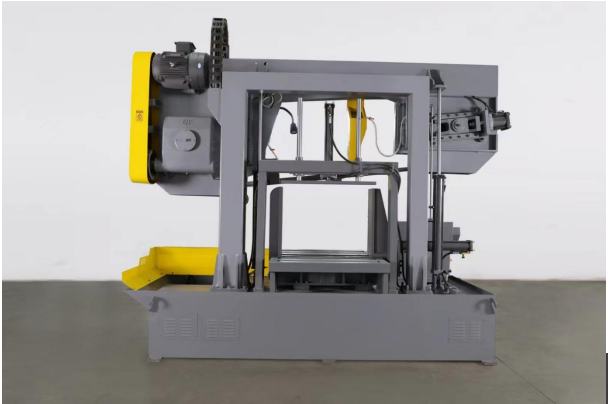

versatility with our Band Saw Machine is a sophisticated machine used for

cutting metal workpieces in a vertical orientation with precision and

automation. This machine combine the capabilities of

traditional vertical band saws with the advanced automation and precision

control offered by numerical control systems.

Overview

Introducing our Metal cutting Band Saw Machine, is a highly versatile machine utilized in metalworking industries for precision cutting of metal workpieces in a vertical orientation. Its primary use lies in automating and controlling the cutting process through CNC (Computer Numerical Control) technology, allowing for precise adjustment of cutting parameters such as speed, feed rate, and cutting depth. This automation enables efficient and repetitive cutting tasks, making it ideal for high-volume production environments where accuracy and consistency are paramount.

A notable special feature of this machine is its programmable cutting patterns, which enable operators to create different cutting sequences with ease, enhancing productivity and versatility. Safety is of utmost importance when operating a Vertical Metal Cutting Band Saw with NC Control, with measures including the use of safety guards to protect operators from moving parts, emergency stop buttons for immediate halting of operations in case of emergencies, and proper training on machine operation and safety protocols to prevent accidents and ensure a safe working environment. Additionally, regular maintenance and inspection of the machine are essential to ensure optimal performance and safety compliance, minimizing risks and maximizing productivity in metalworking operations.

This machine can cut bundles of different diameter pipes, SHS, and RHS Tubes in with ease. First, we have to place those bundles in machine and tight with clamps through machine operations and band saw blade will cut the bundles according to the cutting speed defined in manual for different materials. We can further control the speed of the cutting blade through inverter of this machine.

They main parameter of this machine are as follows:

Cutting

capacity(mm)

|

500mm

for Round shape , 500X600 for square shape

|

Blade

speed(m/min)

|

23/44/71

|

Blade

size(mm)

|

41×1.3×5640

|

Main

Motor(kw)

|

4/6P

|

Hydraulic

Motor(kw)

|

1.5

|

Coolant

Pump(kw)

|

0.09

|

Work-piece

Clamping

|

Hydraulic

Vise

|

Blade

Tension

|

Manual

|

Main

Drive

|

Worm

wheel drive

|

Material

feed

|

Auto

|

FEEDING

LENGTH

|

1000mm

|

Machine

size

|

2600×2200×2000

|

Machine

weight

|

3300kgs

|

Blade

cleaning brush

|

Power

blade cleaning brush

|

NC

control

|

Yes

|

Saw

frame height selector gauge

|

Automatic

work height control

|

Features

|

NC Control The numerical control system allows for precise control over cutting parameters and automation of cutting sequences. Programmable Cutting Patterns Operators can program the machine to create different cutting patterns and sequences, increasing efficiency and productivity. Programmable Cutting Patterns Operators can program the machine to create different cutting length and quantity with 10 variations, increasing efficiency and productivity. Variable Cutting Speed This machine has a feature of variable speed controls, allowing operators to adjust the cutting speed based on the material being cut and the desired cutting results. Automatic Blade Tensioning This machine include automatic blade tensioning systems that maintain optimal blade tension throughout the cutting process. Blade Guides Blade guides support the blade and ensure accurate and straight cuts, minimizing blade deflection and vibration. Safety Safety features such as safety guards, emergency stop buttons, and interlocks ensure safe operation of the machine. |

Application

DeliveryAt HITECH Automation, we offer comprehensive support throughout every stage of your project. This means we not only manufacture the perfect Standing Pallet Stacker to meet your specific requirements but also provide delivery services. Handling materials, whether for large or small projects, can be a challenging task. That's why our team of fencing solution experts is always at your service to provide guidance, recommendations, and expert services. With our assistance, you can enjoy the benefits of safe and secure product efficiently and effectively. Your satisfaction and safety are our top priorities. WarrantyA Band Saw Machine with a one-year warranty for the Electronic Component and 2years for spare parts provides assurance to the customer regarding the quality and reliability of the equipment. |