Barbed

Wire Machine

Discover

versatility with our Barbed Wire Machine. A barbed wire machine is a specialized piece of equipment used in manufacturing

facilities to produce barbed wire efficiently and consistently.

Overview

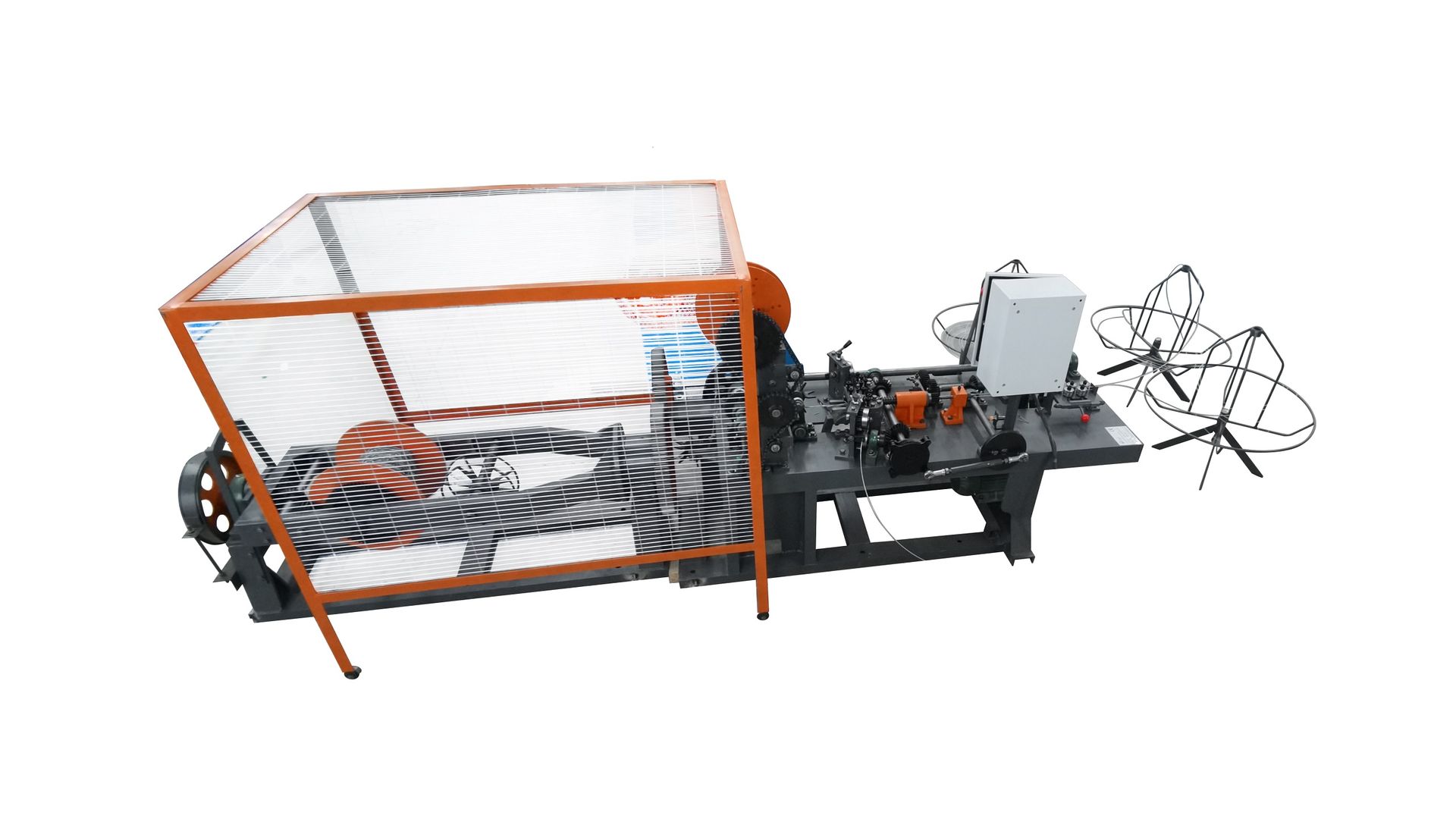

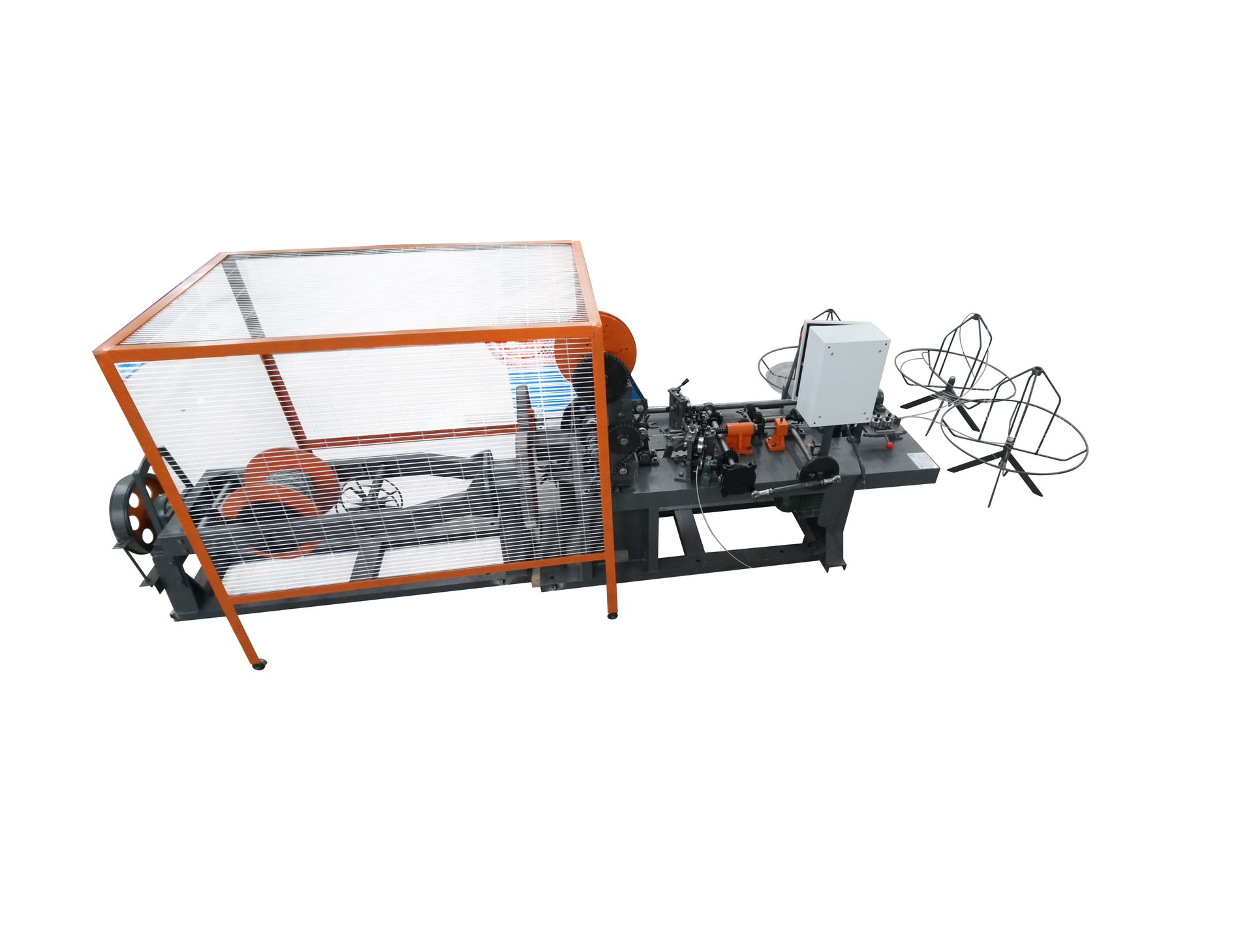

Introducing our Normal Double Twisted Barbed Wire Machine, is an essential industrial apparatus utilized in the manufacturing of double twisted barbed wire, a widely used fencing material known for its effectiveness in perimeter security and deterrence.

This machine efficiently processes galvanized wire into double twisted barbed wire by twisting wire strands together and attaching barbs at regular intervals. Its versatility enables the production of various wire gauges and barb spacing configurations to suit different fencing applications.

A standout special feature of the Normal Double Twisted Barbed Wire Machine is its adjustable settings for wire and barb spacing, allowing for customization of the barbed wire to meet specific customer requirements. With this machine we can handle wire diameter from 1.7-2.8mm with spacing from 3”, 4” and 5” with ease.

Safety is paramount during the operation of the machine, with integrated safety features such as emergency stop buttons to prevent accidents and ensure operator protection. Regular maintenance and inspection of the machine are essential to identify and address any potential safety hazards, ensuring continued safe operation and the protection of personnel in the workplace.

The main Parameters of a Barbed Wire machine include:

Model

|

CS-A

Normal Double Twisted

|

Motor

POWER

|

3.0kw

|

Output

|

150-200Kgs/h

|

Weight

|

1500kgs

|

Barb

space

|

3''

4'' 5''

|

Rated

Voltage

|

380V,50HZ(transformer

)

|

Strand

Diameter

|

1.8-3.0mm

|

Wire

Diameter

|

1.7-2.8mm

|

Features

|

Wire Feeding Mechanism The machine is equipped with a wire feeding mechanism that supplies the raw material (usually galvanized steel wire) to the manufacturing process. Barb Forming Unit This unit shapes the wire into barbs, typically using a series of dies or rollers to create the characteristic sharp points and twists of barbed wire. Twisting Mechanism The machine includes a twisting mechanism that twists together the barbed wire strands with plain wire strands to form the final product. Wire Tensioning System Ensures proper tensioning of the wires during the manufacturing process to maintain uniformity and consistency in the barbed wire. Speed Control This option allows operators to adjust the production speed according to specific requirements and material properties. Safety Features Incorporates safety features such as guards and emergency stop mechanisms to ensure operator safety during operation. |

Application

DeliveryAt HITECH Automation, we offer comprehensive support throughout every stage of your project. This means we not only manufacture the perfect Standing Pallet Stacker to meet your specific requirements but also provide delivery services. Handling materials, whether for large or small projects, can be a challenging task. That's why our team of fencing solution experts is always at your service to provide guidance, recommendations, and expert services. With our assistance, you can enjoy the benefits of safe and secure product efficiently and effectively. Your satisfaction and safety are our top priorities. Warranty

Warranty

will be for One year, and we will provide the technical support for the whole

life.

|