Pipe Bending Machine

Discover

versatility with our Pipe Bending Machine, able to bend Pipe in any manner you

want with our diverse mold available with us. We can make this mold according

to your requirements to meet your needs best.

Overview

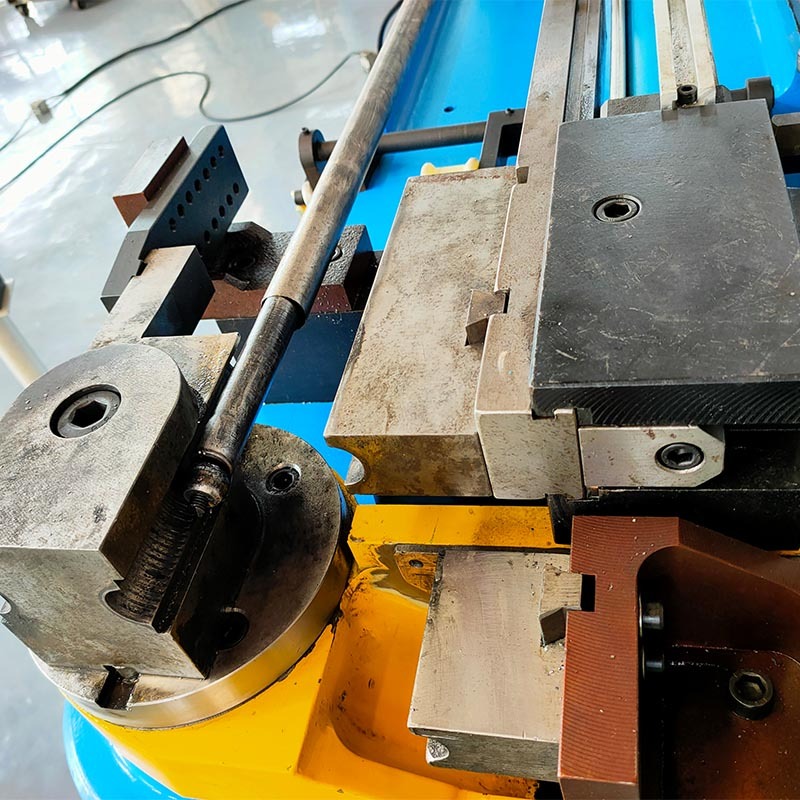

Introducing our Pipe Bending Machine, used to bend Pipes in any manner you want according to your needs. Pipe bending machines are essential in industries such as automotive, aerospace, construction, and manufacturing, where accurately bent pipes and tubes are required for various applications. They offer versatility, precision, and efficiency, making them indispensable in modern production processes.

A notable special feature of this machine is its ability to perform complex bends with minimal operator intervention, thanks to advanced software and servo-driven hydraulic systems. This capability not only enhances productivity but also allows for the fabrication of highly customized components with tight tolerances, making the machine indispensable for industries requiring efficient and accurate pipe bending solutions. This machines maximum bending degree is about 190 and it can handle various sizes of pipes including,16mm, 22mm, 25mm, 33mm, 48mm round pipe easily along with one more 35x35mm square tube with special mold of this machine.

The self-diagnostic system integrated into a 2-axis hydraulic CNC automatic pipe bending machine is a critical safety feature that enhances operational efficiency and minimizes downtime. This system continuously monitors various components and parameters of the machine, including hydraulic pressure, servo motor performance, sensor readings, and software functions. By analyzing this data in real-time, the self-diagnostic system can detect abnormalities, malfunctions, or potential issues before they escalate into more significant problems. It provides immediate alerts or notifications to operators, allowing them to take proactive measures such as troubleshooting, maintenance, or adjustments to prevent unexpected breakdowns.

Max

bending capacity

|

Φ38mmX2mm

|

Max

bending radius

|

R180mm

|

Min

bending radius

|

According

to pipe diameter

|

Max

bending degree

|

190°

|

Max

feeding length

|

4000mm

|

Feeding

method

|

Clamping/direct

feeding

|

Working

Bending Speed

|

Max

90°/s

|

Working

Rotary speed

|

Max

160°/s

|

Working

Feeding speed

|

Max

1200mm/s

|

Bending

accuracy

|

±0.1°

|

Rotary

accuracy

|

±0.1°

|

Feeding

accuracy

|

±0.1mm

|

Bending

method

|

Hydraulic

bending (2A)

|

Hydraulic

motor power

|

5.5kw

|

Feeding

servo motor power

|

750w

|

Rotary

servo motor power

|

400w

|

Max

storage unit

|

1000groups

|

Max

oil pressure

|

14Mpa

|

Machine

weight

|

1600kg

|

Machine

size

|

5200X1000X1700mm

|

Features

Using industrial touch screen, with the simple operation interface in English; high precision, high degree of automation and multi-functional; each action of machine is controlled by PLC programmer control system.

- Fully automatic and CNC pipe bending machine.

- Equipped with servo motor programmable axis.

- Feeding: servo motor drive; Rotation: servo motor drive.

- Bending: hydraulic and encoder control.

- Imported hydraulic system and PLC (standard) unit.

- Automatic lubrication system for moving areas.

- Self-diagnostic system, detecting the error immediately.

- Multiple groups pipe-bending information storage.

- Electric cabinet cooling fan and the hydraulic cooling system ensure the equipment long-time work stably under the high temperature.

- Touch screen and human/machine interface control provide user friendly operations.

ApplicationPipe bending machines find applications across various industries where the bending of pipes and tubes is necessary to create components for specific purposes. Some common applications of pipe bending machines include:

DeliveryAt HITECH Automation, we offer comprehensive support throughout every stage of your project. This means we not only manufacture the perfect Standing Pallet Stacker to meet your specific requirements but also provide delivery services. Handling materials, whether for large or small projects, can be a challenging task. That's why our team of fencing solution experts is always at your service to provide guidance, recommendations, and expert services. With our assistance, you can enjoy the benefits of safe and secure product efficiently and effectively. Your satisfaction and safety are our top priorities.

Quality

guarantee and after-sales service

A

pallet stacker with a one-year warranty provides assurance to the customer

regarding the quality and reliability of the equipment

|